by: Tammy DeRamo, P.E.

Technical Director

With the shift in the energy industry and the aging out of old power generation facilities, many clients are faced with the challenge of remediating the land for future use. One particularly challenging contaminant is coal combustion residuals (CCRs). The geotechnical properties of CCRs vary greatly within each CCR unit and from plant to plant. The material properties are affected by the coal type, conveyance method, plant processes, and age, to name a few. Envirocon has been actively working at the Savannah River Site (SRS) in southwestern South Carolina for the past several years assisting in the closure of their D-Area facilities.

The D-Area Power Generating Facility was the largest energy generation facility at the SRS with a capacity of 20 mega-watts, approximately one half of the electrical demand at SRS. The co-generation facility operated for nearly 60 years, from 1953 to 2012. Through its operational life, CCRs were managed onsite in landfills and surface impoundments. As part of the retirement and closure of the overall facility, Envirocon started closure of the D-Area CCR facilities in March 2015, and the project is scheduled for completion in August 2018. Closure of the D-Area CCR facilities included closure of a 24-acre landfill; 14- and 46-acre surface impoundments; and a 13-acre coal pile runoff basin. Closure methods included dewatering the CCR materials, consolidating CCRs into two facilities to reduce the overall footprint, and capping the facilities with engineered cover systems.

Closure of the facilities occurred in two phases. Phase I included the 24-acre landfill and 14-acre surface impoundment. Envirocon closed the 12-acre coal pile runoff basin and 46-acre surface impoundment as part of Phase II.

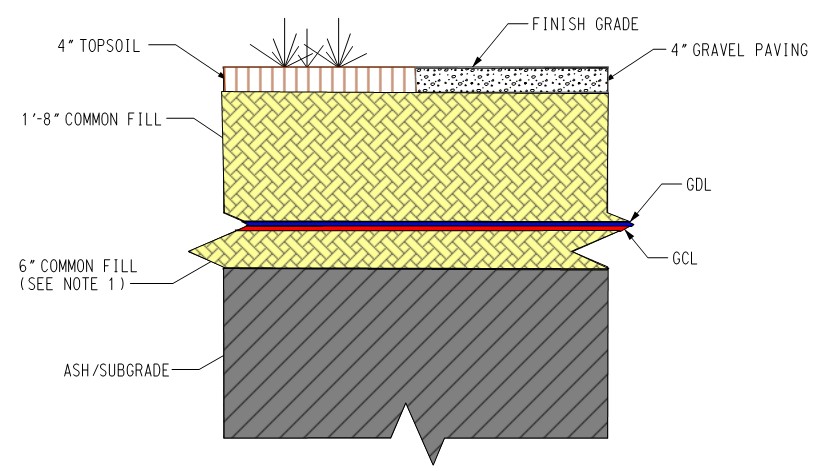

Figure 1. Phase I Final Cover

During Phase I, Envirocon excavated, hauled, and placed all CCRs from the surface impoundment into the 24-acre landfill, totaling approximately 107,100 cubic yards (cy). Crews then compacted and graded the placed CCRs to achieve final grades on the landfill. The project team capped the landfill using 1,908,200 square feet (sf) (43.8 acres) of geosynthetic clay liner (GCL) and geocomposite drainage layer (GDL); 167,900 cy of cover soils; and 1,655,400 sf (38 acres) of sod. Figure 1 shows the liner design. Our team then restored the surface impoundment to a stormwater collection basin.

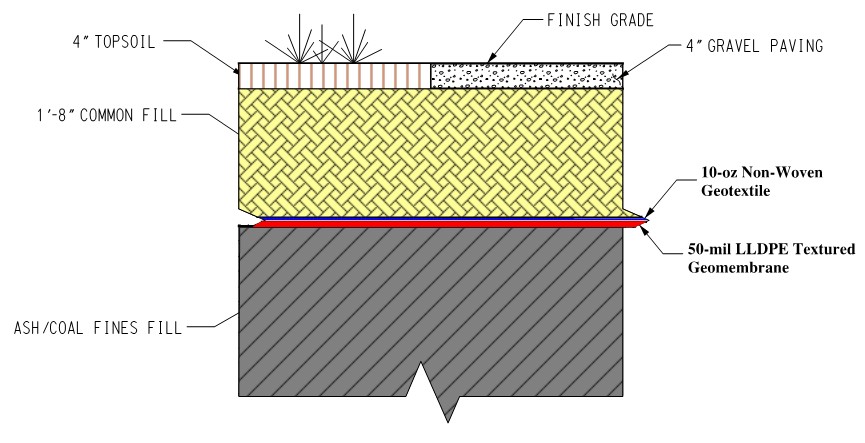

For Phase II, Envirocon removed all CCRs from the west half of the 46-acre surface impoundment, and hauled and placed them in the east half of the surface impoundment, which reduced the overall footprint of the CCR unit by half. Also during Phase II, crews removed CCRs from the inlet basins and coal pile runoff basin, the latter of which was restored to a stormwater retention basin. Envirocon, along with its liner subcontractor, developed a value engineering proposal to replace the geosynthetic material in the engineered capping system. The proposal was accepted, thus accelerating the schedule and reducing the cost. This ultimately saved the project more than $300,000. Quantities from Phase II included 366,000 cy of CCRs; 210,000 cy of common fill; 1,696,000 sf (39 acres) of geomembrane and geotextile; 2,690,000 sf (62 acres) of grass; and 4,100 linear feet of pipe. Figure 2 shows the liner design for the Phase II cover.

Figure 2. Phase II Final Cover

Initially, the CCRs were saturated and required dewatering and processing prior to hauling. In order to access the facilities, Envirocon constructed temporary haul roads. Once equipment had safe access to the CCRs, crews initiated dewatering and excavation of rim and interior ditches, followed by stacking. Our team then hauled, placed in narrow lifts for drying, and compacted the CCRs. Compaction testing consisted of proof rolling using a 25-ton piece of equipment. Confirmation of compaction was assessed through visual observations of deflection.

Considering these various factors, proof rolling allowed for direct confirmation of the required compaction over the entire lift versus other field testing methods, which occurred based on the volume of material placed (i.e., once every 5,000 cy). Envirocon developed a site-specific process to lower the moisture content and achieve compaction of the saturated CCRs. Our experienced project personnel refined and improved the means and methods for handling saturated CCRs throughout the project, and the efforts resulted in cost and schedule efficiencies. At the end of Phase II, which is scheduled for completion in August 2018, 96 acres will be closed and capped – on time and within budget.